in the present hyper-competitive world wide marketplace, makers are frequently looking for approaches to improve effectiveness, minimize expenditures, and manage the highest amounts of excellent. standard methods of high-quality control are sometimes time-consuming and liable to human mistake. This is when vision measurement equipment suppliers are stepping in with ground breaking remedies which might be revolutionizing production procedures. This information will delve into how State-of-the-art vision measurement technological innovation, especially concentrating on Easson's reducing-edge three-axis CMM machines, is not simply Conference current calls for, but actively long run-proofing the entire producing industry.

Table of contents:

AI Integration and Automation: another Frontier in Measurement

Real-Time facts Examination: Minimizing Downtime, Maximizing Output

Easson’s three-Axis CMM: Leading the demand in Scalability and Adaptability

AI Integration and Automation: the subsequent Frontier in Measurement

The combination of synthetic Intelligence (AI) and automation is no more a futuristic idea; it’s a existing-working day reality radically boosting the capabilities on the vision measurement machine. AI algorithms empower these equipment to learn from wide datasets, autonomously enhance measurement parameters, and discover even quite possibly the most subtle defects with unparalleled pace and precision. This interprets to a substantial reduction in human intervention, reducing the potential risk of errors and accelerating inspection occasions. automatic dealing with methods further streamline functions by seamlessly incorporating measurement processes into the prevailing creation line, resulting in a really economical and optimized workflow. The enhanced throughput makes it possible for producers to fulfill demanding creation schedules with no compromising top quality.

actual-Time Data Assessment: more info Minimizing Downtime, Maximizing Output

Real-time facts analysis is proving being a pivotal tool for suppliers striving to minimize expensive output downtime. present day vision measurement devices are now equipped with strong software package platforms effective at providing rapid and actionable feedback on significant Proportions, tolerances, and system variations. This instantaneous knowledge stream permits proactive identification of potential troubles, for instance premature Resource put on, equipment calibration deviations, or product inconsistencies, prolonged before they escalate into major defects or catastrophic creation stoppages. By leveraging this genuine-time intelligence, brands can apply quick corrective actions, improve approach parameters, and in the end make sure continual, uninterrupted creation while minimizing squandered resources and scrap product.

Easson’s 3-Axis CMM: major the demand in Scalability and Adaptability

Easson's 3-axis CMM (Coordinate Measuring Machine) devices are with the vanguard of eyesight measurement engineering, giving unparalleled scalability and adaptability to fulfill the evolving requirements of contemporary manufacturing. These equipment are meticulously engineered to support a diverse variety of part dimensions, intricate geometries, and various material varieties, building them Preferably suited to a broad spectrum of manufacturing applications, from aerospace to automotive. As specific on https://zh-easson.com/products/visual-video-cmm-measurement-machine-with-3-axis-001%CE%BCm-linear-encoder, Easson's equipment are renowned for their Remarkable accuracy, boasting outstanding 0.001μm linear encoders, guaranteeing the highest achievable amount of precision and repeatability. Their modular style facilitates seamless upgrades and customizations, letting makers to adapt swiftly to shifting manufacturing specifications and technological improvements with out incurring substantial cash expenditure. Also, Easson's unwavering dedication to person-pleasant computer software interfaces and extensive coaching packages ensures a seamless integration approach and optimal utilization in their Superior technology, empowering operators To maximise the equipment’s opportunity.

In summary, vision measurement technologies signifies excess of just a classy excellent Regulate Software; it is a strategic essential for producers trying to get to long run-proof their operations and maintain a competitive edge in the present demanding market. By embracing the strength of AI integration, real-time information Evaluation, and remarkably scalable solutions like Easson's Highly developed 3-axis CMM equipment, brands can achieve unparalleled amounts of precision, drastically lower downtime, optimize output effectiveness, and in the long run generate sizeable improvements in profitability. The strategic investment In this particular transformative technological innovation will not be basically a choice but a requirement for extensive-phrase accomplishment. Take the proactive step to check out how Innovative eyesight measurement answers can empower your small business to prosper during the ever-evolving producing landscape, and arrive at out to your trustworthy vision measurement equipment provider to discuss your specific wants and requirements these days.

Tatyana Ali Then & Now!

Tatyana Ali Then & Now! Charlie Korsmo Then & Now!

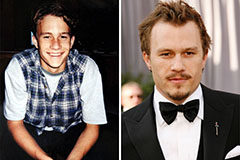

Charlie Korsmo Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Michael C. Maronna Then & Now!

Michael C. Maronna Then & Now! Naomi Grossman Then & Now!

Naomi Grossman Then & Now!